After constructing and deconstructing the arched pavilion at two Oregon State University locations, we were curious about how the flat plywood components could be reused. The Fall 2023 Timber Tectonics students imagined alternative designs and then Nancy Cheng worked with assistants and Design Development Media students to design new pieces to extend the toolkit’s flexibility for new applications.

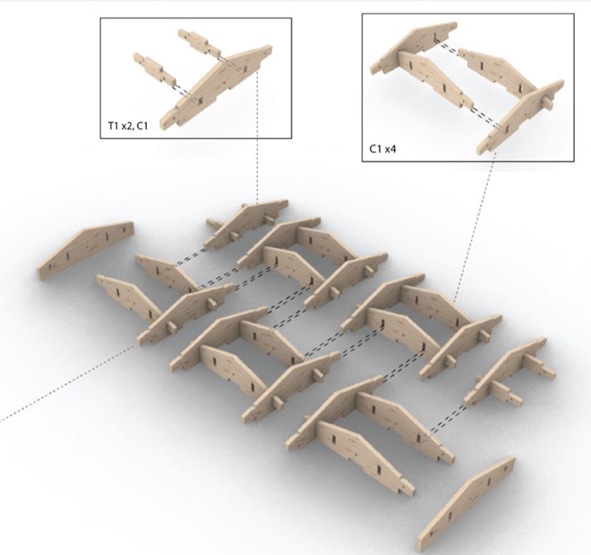

Designers need time to experiment with the components to understand the basic structural system. Replicating the original geometry is the first step towards improvising new configurations. Therefore to support reusability ideas, the original and new corner components were laser cut out of 3mm (1/8”) plywood at 1:6 scale. The kit-of-parts is comprised of 192 copies of a standard piece that create a flat reciprocal frame, along with specialized corner, edge, base and face components.

Proposed new pieces include

- New corner pieces to connect flat panels at different angles

- A Y-shaped piece to support adjacent arched canopy bays

- Modified standard elements to create shelves, benches and supports

Abstracting the complexity of a system helps expedite Design for Reuse. Working with simplified 2D planar modules rather than the actual component shapes allows quick visualization of alternate configurations. For a quick demonstration, flat panels of the original arch were connected with new corners into a folded wall, a registration desk backdrop for the student-run University of Oregon HOPES conference. Wall design and prefabrication of the panels took about 6 hours, on-site assembly about 3 hours and disassembly 2.5 hours. Participating in the full-scale assembly and disassembly helps students understand Design for Reuse and the possibility of rapid construction.

Leave a comment