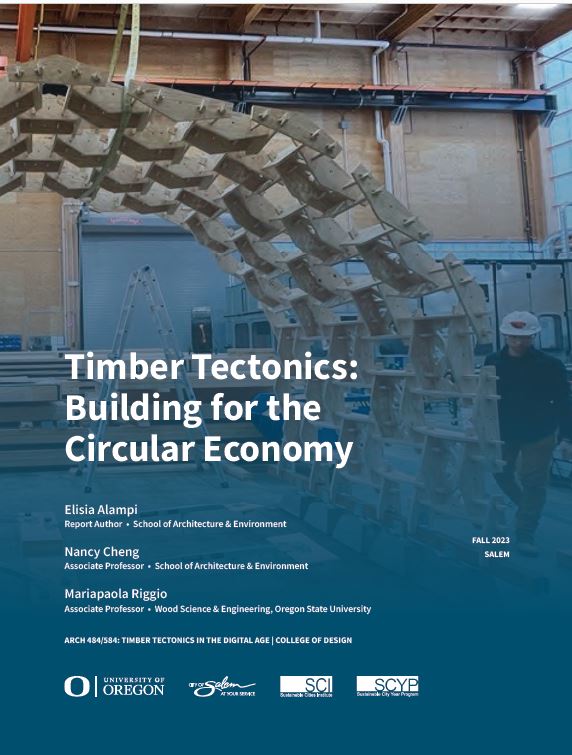

OVERVIEW: Exploring Design for Deconstruction and Reuse of panel materials, the Fall 2023 Timber Tectonics project centers on the adaptable nature of reciprocal frame construction, in which mutually supporting small members join to create a larger span than the length of individual members.The University of Oregon (UO)-Oregon State University (OSU) small groups generated several ideas for a small seasonal pavilion in Salem, Oregon’s Highland Park. Following a review, the class united to consolidate the best concepts into a single project. Operating as one team, the class developed construction details, prefabricated components, and sequenced on-site assembly. The OSU-UO Tallwood Design Institute’s (TDI) Emmerson Lab, UO College of Design woodshop, and CNC WoodCutters used Computer Numerical Controlled (CNC) routing to generate trial and final components. Student-led assembly and installation took place in Week 10, with a final review and installation in the Emmerson Lab. The insights of the review, along with the work of the term, culminated with many lessons learned and a new set of guidelines for an outdoor installation in Highland Park.

The joint class succeeded in putting together the pavilion for the December 1, 2023 final review and then the following week disassembled it into sections. On February 20, 2024, the pieces were reassembled in OSU’s Peavy Hall in less than 6 hours.

COMPREHENSIVE REPORT

Acknowledgements

-

- This effort is partially supported by a grant from the U.S. Department of Agriculture’s Agricultural Research Service (USDA ARS) [Agreement No. 58-0204-2-143]

-

- Tallwood Design Institute (TDI) supported this inquiry into Building for the Circular Economy with reusable, reconfigurable components

-

- TDI staff Phil Mann, Mark Gerig, and Byrne Miyamoto provided Computer Numerical Control (CNC) routing and construction support

-

- UO College of Design Fabrication manager Tom Coates worked patiently with the students to guide successful CNC cutting of multiple prototypes in Eugene

-

- UO Sustainable City Year Program funded crucial expenditures, connected us to the City of Salem’s Strategic Initiatives Manager Courtney Knox Busch and Parks Planning Director Robert Romanek, leading to participation of Engineers Aaron Kimsey and Ryan McGraw and Highland Park resident stakeholders

-

- Roseburg Forest Products contributed the plywood used in the project

-

- The OSU Department of Wood Science supported the studio by allowing the assistance of OSU PhD student Alireza Yari.

-

- The UO Department of Architecture supported the studio with a research grant that allowed hiring of B.Arch. student Grayson Wright to assist the class

-

- The UO Women of Color Summer Writing Fellowship provided funds to hire research assistant Josh Weber for initial explorations, which were done with the help of Justin Tuttle, UO Portland Workshop Technician

Instructors

-

- Mariapaola Riggio, OSU Department of Wood Science and Engineering

- Nancy Cheng, UO Department of Architecture

Student Participants

-

- Architectural Design: Braden Lawrie, Yasmeen Sundareswaran, Seunghyeon Park, Michelle Jayawickrama

-

- Structural Design: Nick Thielsen, Lara Diehm, Jackson Megy, Rory Doerksen

-

- Joints and Connections: Charlotte Kamman (UO Project Manager), Elisia Alampi, Anthony Newton, Harvey Smith

-

- Rain Protection & Additional Components: Nic Ernst, Igor Tiago-Lopes (OSU Project Manager), Marie Lee

-

- Fabrication: Jin-wei Chu, Sage Fetkenhour, Bryan Sherlock, Andrew Kesterson

In December 2023, Nancy Cheng presented workshops using reciprocal frame scale components at RheinMain Hochshule in Wiesbaden, Germany and University of Hasselt’s Building Behind Borders’ postgraduate program, Belgium. The ideas were presented at the AIA/ACSA Intersections 2023 conference in Amherst, MA, and will be presented at the International Association for Space Structures in Zurich, August 2024.

Leave a comment